From Permit to Power-On: How Data Centers Actually Get Built

A clear look at the real timelines, constraints, and risks that shape data center delivery from site selection to power-on.

Welcome to Global Data Center Hub. Join investors, operators, and innovators reading to stay ahead of the latest trends in the data center sector in developed and emerging markets globally.

This article is the 14th article in the series: From Servers to Sovereign AI: A Free 18-Lesson Guide to Mastering the Data Center Industry

Building a data center looks linear from the outside, but the real timeline begins the moment a site is identified.

Before any contractor mobilizes, early-stage work determines zoning outcomes, environmental approvals, interconnection feasibility, and community backing. These steps decide whether a project advances or stalls.

Timelines are critical.

Tenants plan capacity precisely and will shift providers if delivery slips. Lenders and investors price around schedule certainty, and missed milestones erode returns. Developers who regularly fall behind lose credibility and with it, the ability to win major deployments.

The Clock Starts Before Concrete

The pre-construction phase often lasts a year or more.

It covers land-use approvals, environmental assessments, interconnection studies, noise and generator reviews, and an expanding set of community consultations. Each moves at its own pace a zoning amendment can take months, an environmental review can stretch into a second year, and utilities may delay commitments if system upgrades are required.

These steps shape the project early.

They determine whether a 20MW plan can scale to 80MW, whether water or discharge limits constrain cooling, and whether the political climate can support the size of the development. Some jurisdictions welcome data centers; others face pushback over noise, diesel use, visual impact, and grid strain.

This is why permitting is the first real test. A smooth path enables a reliable schedule. A contested one creates multi-year uncertainty.

The 3 Phases of Data Center Development

The development lifecycle spans permitting, construction, and commissioning each with its own risks.

Permitting requires coordination across federal, state, and local agencies.

Large projects may need wetlands or species reviews, state-level environmental and energy permits, and local zoning, building, and fire approvals. Interconnection studies are often the slowest item, with some markets facing multi-year queues. Community opposition can add hearings and redesigns. Water discharge and air quality permits also slow progress. Only a few markets offer faster paths where zoning and utility capacity are already in place.

Construction begins once approvals clear.

Early work covers grading, duct banks, drainage, and foundations, followed by steel or concrete shells built for heavy mechanical and electrical loads. The core tasks involve installing transformers, switchgear, UPS systems, distribution gear, and cooling. Teams often overlap design and construction and rely on standardized layouts or prefab components to shorten schedules. The biggest risk in this phase is equipment lead time transformers may take two to four years, switchgear months, and generators or cooling equipment similarly long. Without early procurement, timelines slip even if on-site work stays on track.

Commissioning converts a completed building into an operational facility.

It starts with equipment checks, then system-level testing of power and cooling, ending with integrated tests under load, including utility loss, generator start, UPS transitions, and redundancy validation. Hyperscalers often bring their own commissioning teams and will not approve a facility until it meets their standards. Failures here can trigger months of rework and retesting.

Timelines and Where They Break

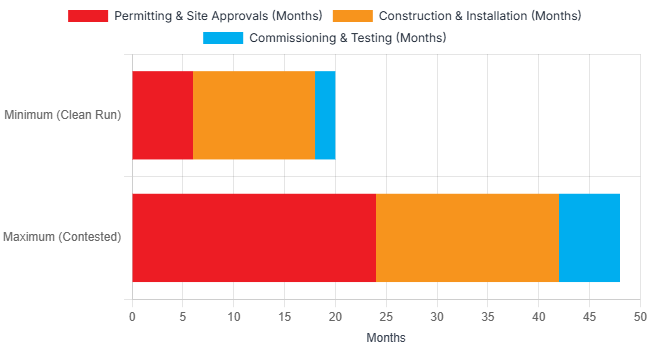

A typical data center project moves through permitting in 6 to 24 months, construction in 12 to 18 months, and commissioning in 2 to 6 months.

A clean run therefore takes 18 to 36 months from land acquisition to power-on and these ranges are widening.

AI demand is pulling timelines forward while permitting grows more complex.

Interconnection studies are often slower than the rest of development combined. Supply chains for transformers and switchgear remain tight. Skilled labor is uneven across markets. A single delay in any one category can stretch the schedule for the entire program.

Most delays are cumulative.

A 3-month slip in permitting, a 4-month slip in equipment delivery, and a 2-month slip during commissioning can stretch a 2-year plan into something far longer.

Speed as a Competitive Advantage

Speed is a meaningful differentiator.

Hyperscalers want capacity delivered on a schedule they can build into their product roadmaps. They will pay more to secure it. Developers who can bring sites online earlier than competitors gain pricing leverage and longer-term relationships.

To move faster, many firms rely on repeatable designs and modular components.

Prefabricated electrical rooms and cooling skids reduce work on site and shorten commissioning cycles. Strong relationships with utilities and planning authorities also help because developers understand how decisions are made and how to prepare complete submissions that avoid rework.

Strategic Risks

Several risks consistently disrupt timelines.

Political shifts can lead to new restrictions on diesel generators, water use, or noise, and those restrictions can apply retroactively.

Design errors and poor contractor coordination lead to rework.

Weather and natural disasters interrupt work or damage incomplete systems.

Price shocks in steel, copper, concrete, cable, and diesel raise costs, create procurement gaps, and place pressure on budgets.

Each of these risks affects time to revenue. Every delay pushes back the moment rent begins and increases the carrying cost of the project. These costs directly impact returns for developers and investors.

Key Takeaways

Time is the central variable in data center development.

It shapes leasing, financing, and long-term customer confidence. The operators who outperform do not rely on speed alone. They create schedules they can meet, procure equipment early, reduce design variance, and treat commissioning as a discipline. Predictable delivery is the real advantage.

A practical question follows from this: would you favor a site with faster approvals and higher construction costs, or one with slower approvals and lower costs?

The choice determines whether your capacity is live when the market needs it or still waiting for permits while demand moves elsewhere.